Harness Maker

Cliquez ici pour la version française

Le Bourrelier / Bourretier | The Harness Maker

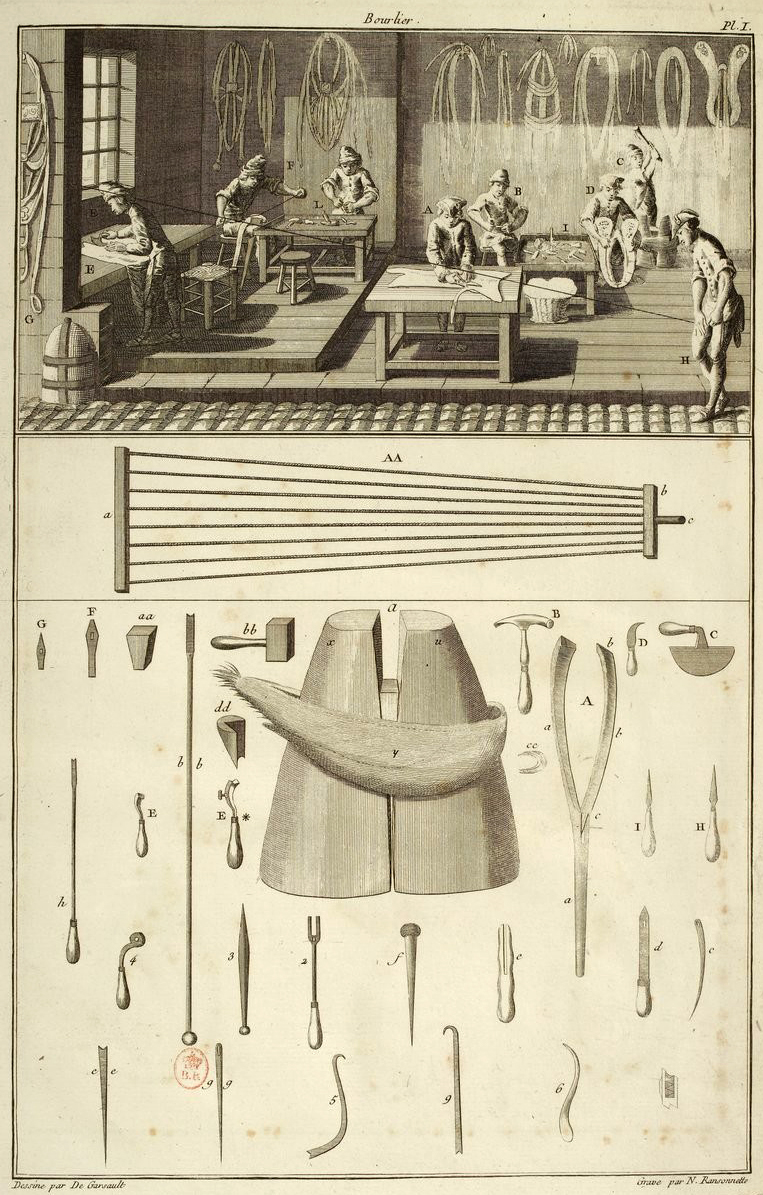

The harness maker’s workshop ("L'art du bourrelier et du sellier", drawing by François-Alexandre-Pierre de Garsault, Bibliothèque nationale de France, https://gallica.bnf.fr).

The French name of the bourrelier or bourretier comes from the word bourre, or stuffing (referring to animal hair or hemp fibre). In the 18th century, the harness maker's work was in high demand, especially in areas with plenty of horses used for coaches and carriages. He made various collars, ranging from simple yokes (for cattle) to work harnesses. He also made horse saddles, as well as stuffing to go underneath the saddles. The harness maker had to know how to properly drive in nails and rivets, cut metal hardware and other pieces of metal.

On occasion, he would also stuff seats for vehicles. To make the stuffing, the harness maker needed leather, wood, iron, horsehair, sea foam or animal hair, linen thread and a large cloth. In coastal communities, like l’Isle-Verte for example, sea foam was often collected and used for stuffing instead of animal hair. Whether sea foam, animal hair or hay was used, the material and the leather had to be wet in order to be manipulated and shaped. The linen thread was either smeared with animal fat or tar when it came time to sew, so that the seams could be tightened properly.

The harness maker mainly worked with sheep leather but also used beef or veal leather (which was of higher quality), fabric and rubber canvas. Other leather came from deer, seals and porpoises. He needed awls to sew the leather, gimlets to pierce the wooden frames of the harness, as well as knives and (hole) punches.

It would take the harness maker about a day of work to complete a harness, as the sewn sections and the padding needed to be very solid. A well-made harness would not bother the animal and would last for the duration of a horse’s life.

Known persons that had this occupation: Charles Dugré, Antoine Mazonné, Antoine Ossant

Meet modern-day artisan harness-maker Bernie Samson in northern Minnesota

Sources:

Claude Lemay, "Fonctions et métiers délaissés", l'Ancêtre, number 281, volume 34, winter 2008, and number 280, volume 34, winter 2007; electronic edition, Société généalogique de Québec (www.sgq.qc.ca/images/_SGQ/R_LAncetre_plus_libre/ENT-FONCTIONS-METIERS-DELAISSES.pdf).

Jeanne Pomerleau, Arts et métiers de nos ancêtres : 1650-1950 (Montréal, Québec: Guérin, 1994), 59-62.